- New type Equpment for manufacturer of Insulator Ball Pin for Glass and porcelain suspension insulator

- Business and mission

- Reference List

- Media Gallery

- Partners

- News

- Main/

- About company/

- Archive/

- News

New type Equpment for manufacturer of Insulator Ball Pin for Glass and porcelain suspension insulator

New type Equpment for manufacturer of Insulator Ball Pin for Glass and porcelain suspension insulator

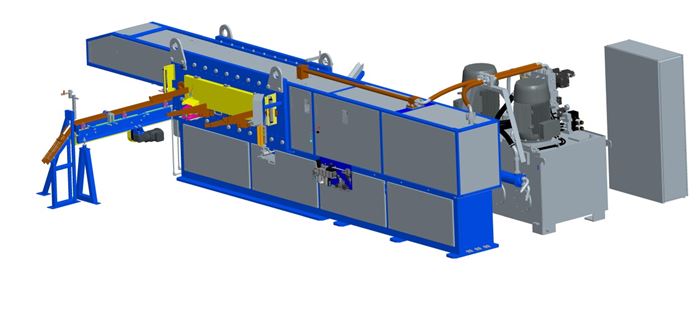

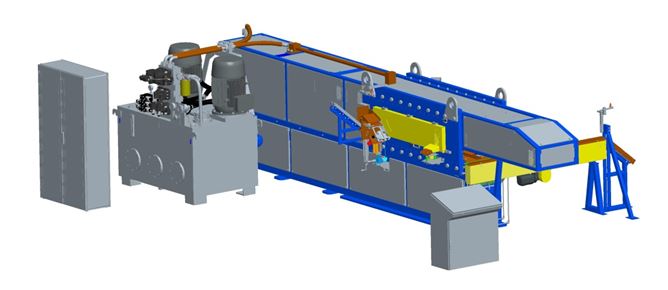

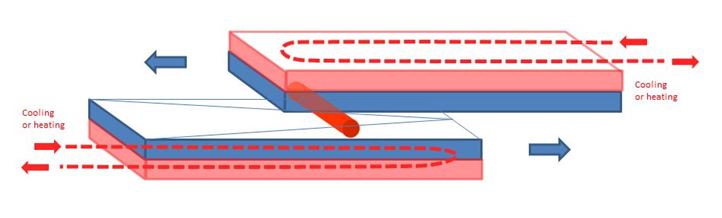

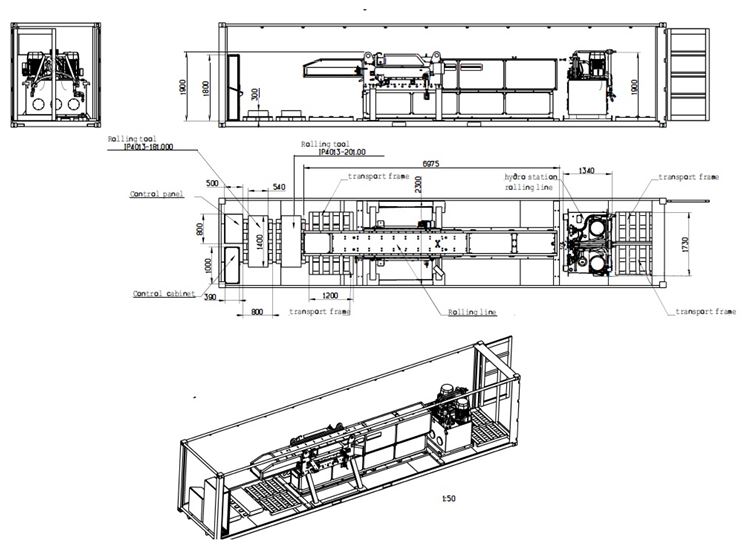

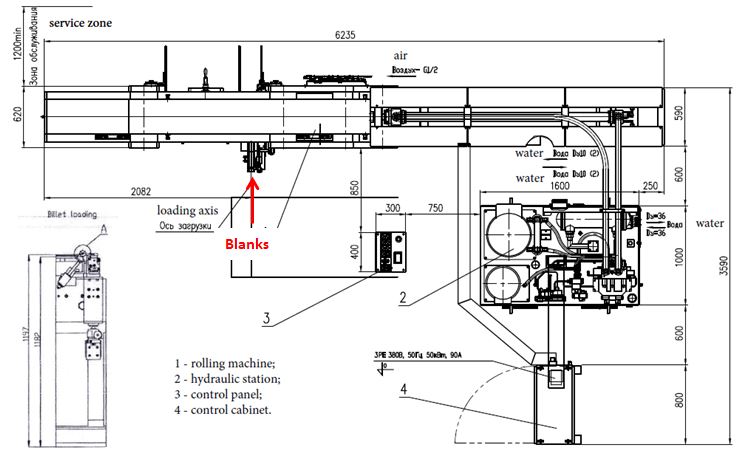

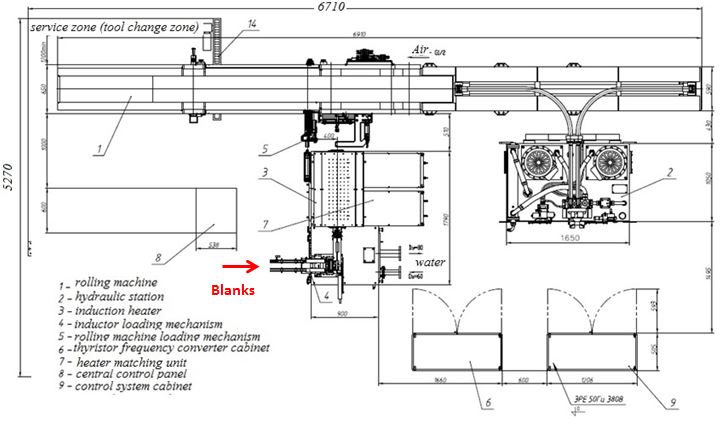

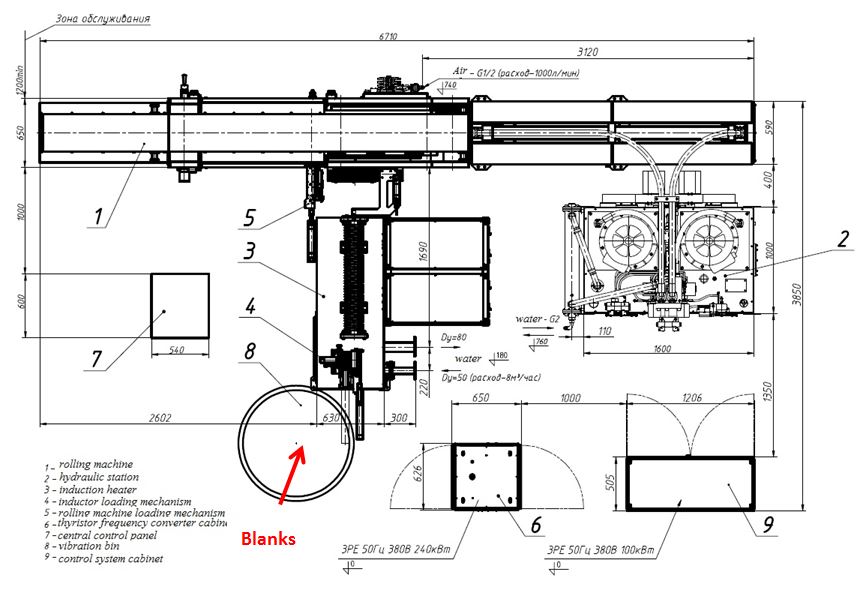

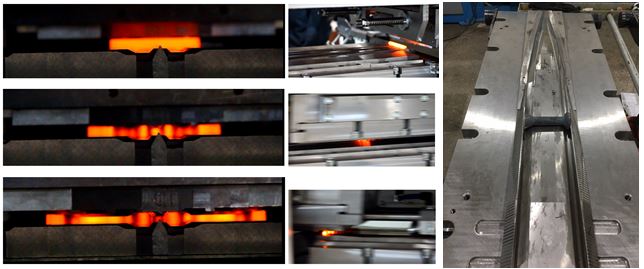

We manufacture process lines for the production of high-voltage insulator rods - flat cross-wedge rolling method new type high metall and time safety technology. The article presents possible options for automation of equipment execution, as well as general technical requirements and conditions for the implementation of this project. The equipment and technologies are already working in 80 implemented projects.

|

№ |

Type |

|

1 |

Cross-wedge rolling line – WRL6012-01 (manual change die tool set, changeover time 20-30 minutes by line operator). This includes temperature control of the workpieces with a pyrometer before feeding them into the machine, as well as a mechanism for rejecting overheated and underheated workpieces. Without heater. |

|

2 |

One tool set WRL6012-01 (standard fixing with bolts on the line). Including design and production. |

|

3 |

Cross-wedge rolling line – WRL6012-02 (automatic hydraulic change die tool set, changeover time 5-10 minutes by (change control from the line operator panel). This includes temperature control of the workpieces with a pyrometer before feeding them into the machine, as well as a mechanism for rejecting overheated and underheated workpieces. Without heater |

|

4 |

One tool set WRL6012-02 (fixing automatic tool changed system). Including design and production. |

|

|

Options |

|

1 |

Induction heating 250 kW-500kW (maximum automatic) of workpieces and automatic feeding of workpieces from a storage hopper volume 2500 kg. This includes temperature control of the workpieces with a pyrometer before feeding them into the machine, as well as a mechanism for rejecting overheated and underheated workpieces. Heating cycle 9-10 seconds |

|

2 |

Induction heating 250 kW-500kW (simplified automation) feeding blanks from a storage tray with a capacity of 10-15 blanks. (loading of the workpiece tray by the operator according to consumption). This includes temperature control of the workpieces with a pyrometer before feeding them into the machine, as well as a mechanism for rejecting overheated and underheated workpieces. Heating cycle 9-10 seconds |

- Production time of the line and one set of rolling tools: 9-10 months

- The equipment and control system complies with USA standards or (Europe, Russian or needed)

- Offer validity period: 20 days;

- Delivery terms: "FCA" Minsk (INCOTERMS-2020) (pickup at the customer's expense);

- Commissioning works are not included in the cost of the equipment and are performed under a separate agreement. These lines are tested on the customer's material before shipment and after delivery, as a rule, in addition to connection, they do not require lengthy commissioning works, and with experience in working with forging and pressing equipment, they allow Customers to independently put them into operation.

- Operation and maintenance manual; a layout solution is provided for the preparation of the production site by the Customer, indicating the locations and requirements for the communications necessary for the line operation.

- General technical drawings (assembly drawings of the main groups);

- Electronic and electrical, pneumatic, hydraulic diagrams;

- To avoid unauthorized changes to the software, the source code of the line control program is transferred after the end of the equipment warranty. Remote service support for the software is provided during the warranty period.

- List of spare parts.

- Frame RAL 5005 blue; moving parts and protective screens: RAL1023 (yellow); Enclosures of cabinets and control panels of the electrical part: RAL7035 (gray) (we do not paint in other colors). It is possible to paint the frame and protective screens (except for cabinets and control panels) in another color (as an option: the color of the frame and painted parts of the equipment - anthracite gray RAL 7016. The color of the moving parts and safety elements - bright orange RAL 2008)

- Line control in automatic mode from the setup and central control panels.

- Standart ambient temperature oC -10oC +50oC.

- Storage temperature oC Max. 70°C (for 24 h)

- Relative humidity % 80

- Production cycle: 6-7 sec ( Line output capacity: single rolling – more 514 parts/hour;

- Line power –100-120kW; (3 phase 480 V 60Hz ). The billet heating unit is not included in the line set

- Cooling water consumption 0,2…0,4 МPa, m3 / h - up to 20 (not more ≤25°С)

- Compressed air 0,4…0,6 МPa, m3 / h – not less than 25 m³ / hour. Use components «Festo», «Camozzi»

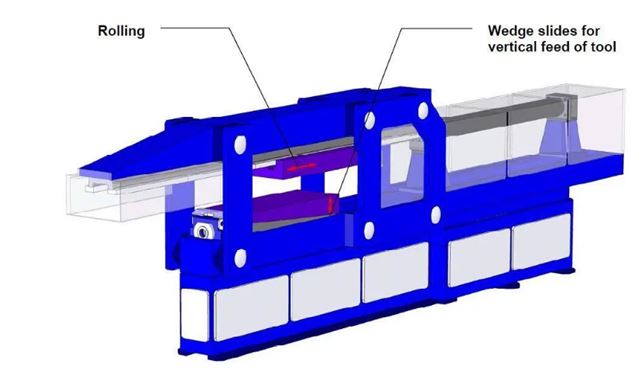

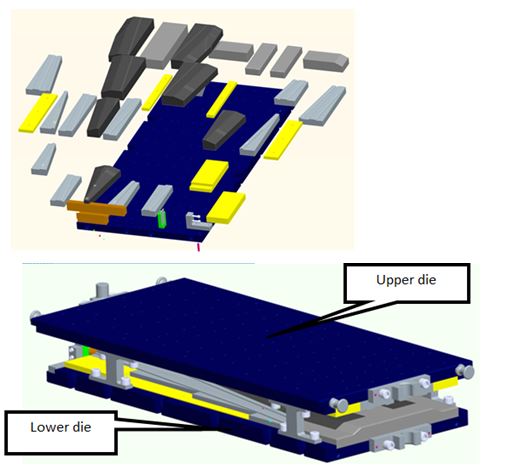

- Parameters for adjusting the closed height of the tool, mm: 158…164

- Movable die length – 1200 mm;

- Die tools forming length – 1200 mm;

- Die tools forming width – 500 mm;

- Time for tool changing – 10-20 minutes (bolt fixed scheme);

- Blank diameter, mm – 10…60 mm;

- Blank length, mm – 60…150 mm;

- Rolling part diameter, mm –10…60 mm;

- Working with heated workpieces heated to temperatures C˚: 900...1200;

- Control System PLC-based, HMI panel (Allen Bradley) consists of a mobile control unit and electric cabinet (on request it is possible to use controllers from other manufacturers);

- Electric cabinet and control panel cabinet “RITTAL”, engress protection: IP65.

- Switching equipment from high quality companies «Telemecanique», «Allen Bradley», «Siemens», «ABB», «Schneider electric»,. Wire – Helukabel ;

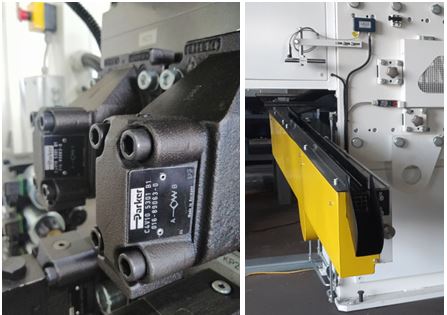

- Gearmotors – «Siemens», hydraulic components – «Parker»;

- Shut height adjustment capability with the remote control during operation;

- Management system that is based on a programmable controller, allows the line to work in the adjustment and automatic modes with the withdrawal of all the settings on the operator panel;

- High degree of automation. Provides smooth and stable operation of the line, with full control of all parameters;

- Weight lines, kg – 11 000

- Rolling machine;

- Block for feeding blanks into the machine;

- Conveyor for removing rolled parts from the machine;

- Pneumatic equipment;

- Hydraulic equipment (hydraulic station, communications connections);

- Control system (control cabinet, control panel, communications connections);

- Tool changer;

- Operation manual, electrical, pneumatic diagrams, etc.

- Induction heater blank (option)

- Accumulating bin with automatic feeding of blanks (option)