- New line for cross-wedge rolling of forgings with a diameter of 48-130 mm with an induction heater of blanks with a capacity of 1600 kW

- Business and mission

- Reference List

- Media Gallery

- Partners

- News

- Main/

- About company/

- Archive/

- News

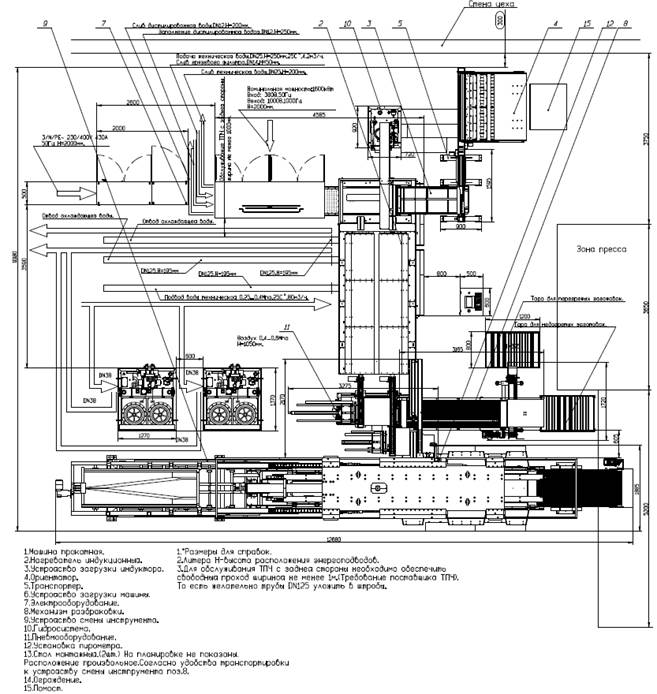

New line for cross-wedge rolling of forgings with a diameter of 48-130 mm with an induction heater of blanks with a capacity of 1600 kW

New line for cross-wedge rolling of forgings with a diameter of 48-130 mm with an induction heater of blanks with a capacity of 1600 kW

We designed, manufactured and supplied a new WRL13025TS cross-wedge rolling line with a flat forming tool for the production of forgings with a diameter of 48-130 mm for hot stamping (rolling and stamping with one heating of the workpiece). Including an induction heating unit with a capacity of 1600 kW 1000 Hz and 5 sets of replaceable inductors.

Included with an induction heating unit with a thyristor frequency converter with a capacity of 1600 kW 1000 Hz and 5 sets of replaceable inductors. The inductors are made in a two-strand parallel design. Each thread is loaded automatically from a common storage slide hopper. The loading mechanism drive is hydraulic. When replacing one inductor size with another, quick changeover is provided (connection of water-cooled pipes with quick-release nipples, fastening of the inductor with quick-release latches). The inductor design (lining) is disassemblable and repairable. Water-cooled guides are provided for moving the workpieces along the inductor.

The installed capacity of the entire equipment complex is 2000 kW. The equipment uses an original dual-circuit cooling system for the main working units of the tool, rolling machine, hydraulic stations, inductors and TFC. Cooling of heated units and line elements is forced water with continuous water supply at a pressure of 0.25...0.4 MPa. Cooling of the TPC is dual-circuit with a heat exchanger. The primary closed circuit with a heat exchanger is connected to the cooling system of the TPC cabinet, the secondary circuit is connected to the process water supply system. The coolant of the primary TPC cooling circuit is distilled water.

The induction heating unit ensures the delivery of heated in the range of +1100˚С - +1250˚С blanks with a diameter of up to 130 mm with a capacity of up to 3100 kg/hour.

The loading unit of the rolling machine ensures automatic delivery of heated blanks from the inductor to the working area of the machine. A device for monitoring the temperature of the blank (pyrometer) is used with the output of its readings to the control panel and a mechanism for removing underheated or overheated blanks coming from the outlet section of the inductor. The blank loading unit in the rolling machine includes a sorting mechanism, which ensures the separation of blanks rejected by temperature into underheated and overheated ones in the appropriate containers.

When rolling forgings with a flat tool on the WRL13025TS line, we have the following advantages:

- higher accuracy of the resulting forgings.

- quick tool change due to the fixation of the rolling tool on the WRL13020TS line using hydraulic clamps controlled from the central control panel (the time for changing a set of tools weighing about 3500 kg is 15-20 minutes).

- installation of the tool does not require additional basing and parallelism adjustment.

- the tool has a cooling system to stabilize the temperature mode of the line in automatic mode.

- flat tool of the WRL and WRL TS mills is easier to manufacture and maintain during regrinding (only part of the replaceable wedges requires repair, when regrinding a round tool, the entire surface of the roll (roller) is regrinded).

- Automatic adjustment of the closed height from the control panel of the rolling line for switching from one diameter of rolled blanks to another.

- equipment for 2-3 shift operation.

- quick start-up of equipment at the customer's site (does not require a special foundation);

- versatility of the rolling line for working with different diameters of blanks (selection from the operator panel)

Cross-wedge rolling line WRL13025TS-01

Mechanism for sorting and monitoring the temperature of a heated workpiece with automatic feeding into the line

Double-inductor induction heating unit for workpieces / view without covers

Устройство автоматической загрузки индуктора / Устройство автоматической подачи заготовок из накопительного бункера

Thyristor frequency converter (TFC) / Control cabinets

Hydroelectric power stations

Tool changer

Sets of replacement inductors 5 sizes

For rolling forgings for stamping or metalworking (ball pins of all sizes, lever forgings, stepped shafts and other types of products) at your production and the production of your partners, we offer the implementation of automatic rolling lines (together with heating of blanks) of our own design and production. We also invite you to visit our company to familiarize you with the specified technology and equipment in detail.

To justify the economic efficiency upon request, we are ready to prepare a technical and economic proposal in accordance with the drawings of parts planned for production provided by you.

Our rolling lines are universal, due to the quick change of tools, they allow us to reduce the time for changing the range of products being manufactured. We design and manufacture rolling lines and tools ourselves, and launch the line at the customer's site, which significantly simplifies the coordination and implementation of projects. Our production lines, delivered to the customer back in the 90s and 20s, are operated at our customers' sites.

If you are interested in implementing cross-wedge rolling lines, please let us know in any way convenient for you.

We are interested in supplying equipment for the production of auto components to Vietnam, the Philippines, India, Türkiye and other countries of the near and far abroad.

CONTACTS:

- Phone: +375 (25) 500-15-23 (Viber and WhatsApp)

- E-mail: amtengine@amtengine.com