- Equipment for hot and semi-hot cross-wedge rolling for the production of forgings of ball pins and ball joints for cars and trucks

- Business and mission

- Reference List

- Media Gallery

- Partners

- News

- Main/

- About company/

- Archive/

- News

Equipment for hot and semi-hot cross-wedge rolling for the production of forgings of ball pins and ball joints for cars and trucks

Equipment for hot and semi-hot cross-wedge rolling for the production of forgings of ball pins and ball joints for cars and trucks

An example of using cross-wedge hot and semi-hot rolling lines for mass production of forgings of ball pins and bearings for automobile and truck equipment. Allows to reduce time, waste, improving quality in the production of auto components.

For mass hot, semi-hot rolling of forgings for stamping of suspension parts (levers, rods, forks) or metalworking of ball pins (steering tips, stabilizer struts, ball pins of suspension arms) for passenger cars, commercial vehicles, trucks, agricultural machinery at your production facilities and the production facilities of your partners, we offer the implementation of automatic rolling lines for cross-wedge rolling with a flat rolling tool (together with heating of blanks) of our own design and production.

The production of a ball pin blank by the method of transverse wedge rolling ensures the strengthening of the obtained blanks due to the creation of a metal structure with a longitudinally elongated crystal lattice, which increases the resistance of the pins to loads compared to traditional methods, for example, with the cold heading method. Due to the redistribution of metal during the shaping of the ball pin forging, rational use of the original blank is ensured, which allows reducing waste by weight commensurate with the obtained forging itself. In the case of using rolled forgings for stamping, it ensures a decrease in the number of stamping operations, increases the service life of the dies, and significantly increases the metal utilization coefficient.

Depending on the planned production volume and the range of manufactured ball studs and other forgings, we offer different versions of rolling equipment (including automation of feeding and heating of blanks).

Option 1. Equipment version for working with ball bearings with blank diameters up to 25 mm

Option 2. Equipment version for working with ball bearings with blank diameters up to 40 mm

Option 3. Equipment version for working with ball bearings with blank diameters up to 80 mm

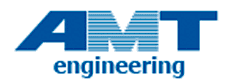

Option 1. Cross-wedge rolling line WRL2510 for rolling ball stud forgings with a maximum diameter of up to 25 mm. Feeding the workpiece into the inductor from the storage chute.

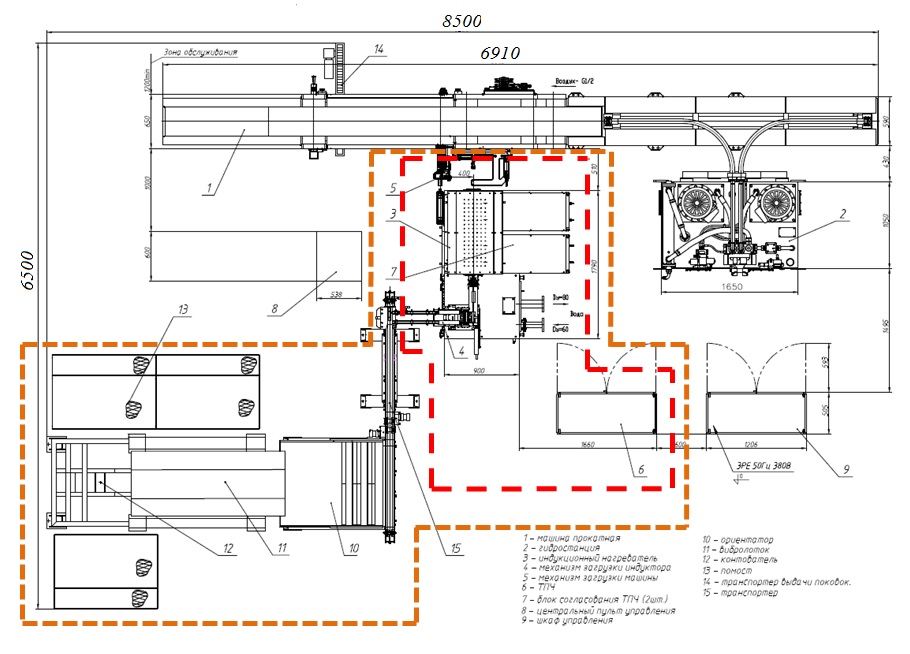

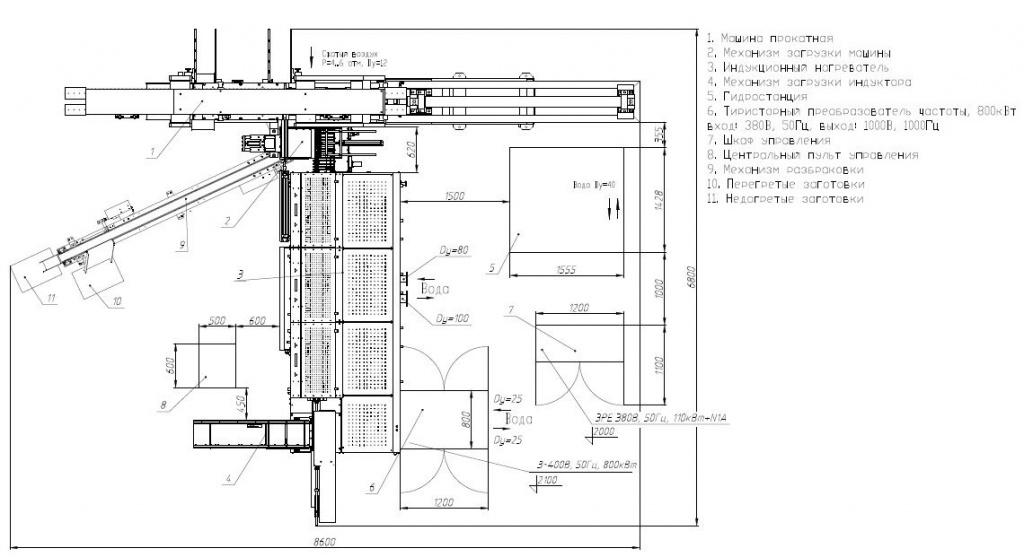

Cross-wedge rolling line WRL2510-01 consisting of:

- Rolling machine;

- Machine loading device;

- Induction heater with transistor frequency converter (TFC);

- Inductor loading device with feed from the workpiece storage chute;

- Automatic workpiece feeding device into the rolling machine with temperature sorting. Workpiece temperature control device with a pyrometer and a mechanism for removing underheated or overheated workpieces coming from the outlet section of the inductor;

- Rolling tool changer.

Purpose indicators:

- Installed capacity of the rolling machine and TPC, kW 100

- Productivity for paired rolling of forgings, pcs/hour 720

- Maximum diameter of the workpiece, mm 25

- Heating temperature of the workpieces, 0С 1000…1200

- Three-phase AC network 380 V and frequency 50 Hz. Compressed air with a pressure of 0.4...0.6 MPa and a flow rate of at least 20 m3/hour. Cooling of heated units by continuous supply of water with a pressure of 0.25...0.4 MPa. Water GOST 6709. Temperature no more than 25 s. Flow rate, 5-10 m3/hour. Control cabinet with PLC, central control panel with HMI control panel and duplicated physical buttons. Separate wired adjustment control panel with physical buttons.

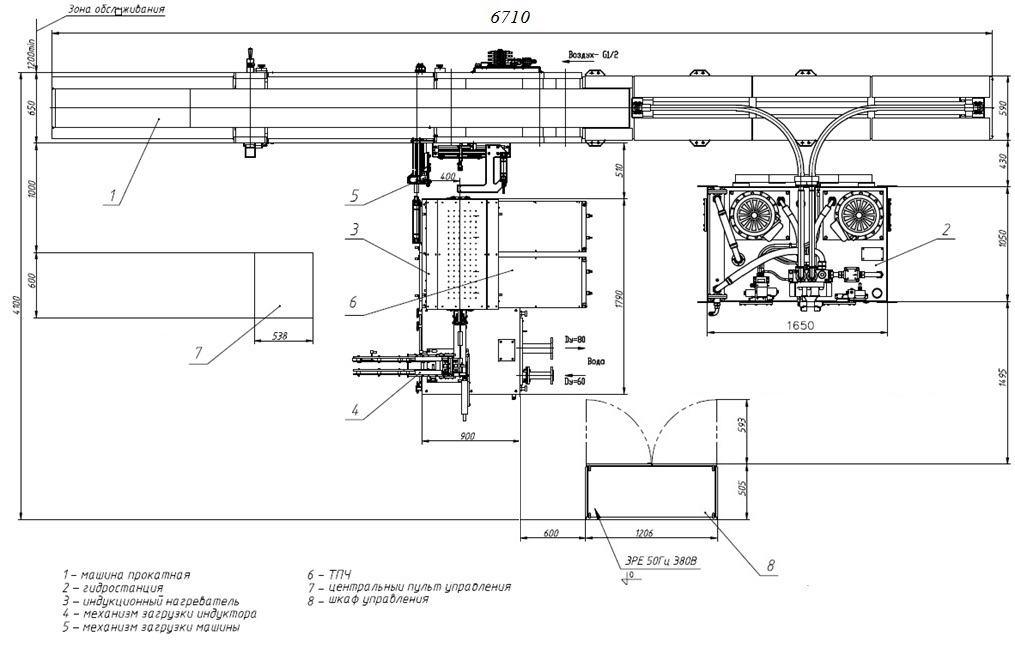

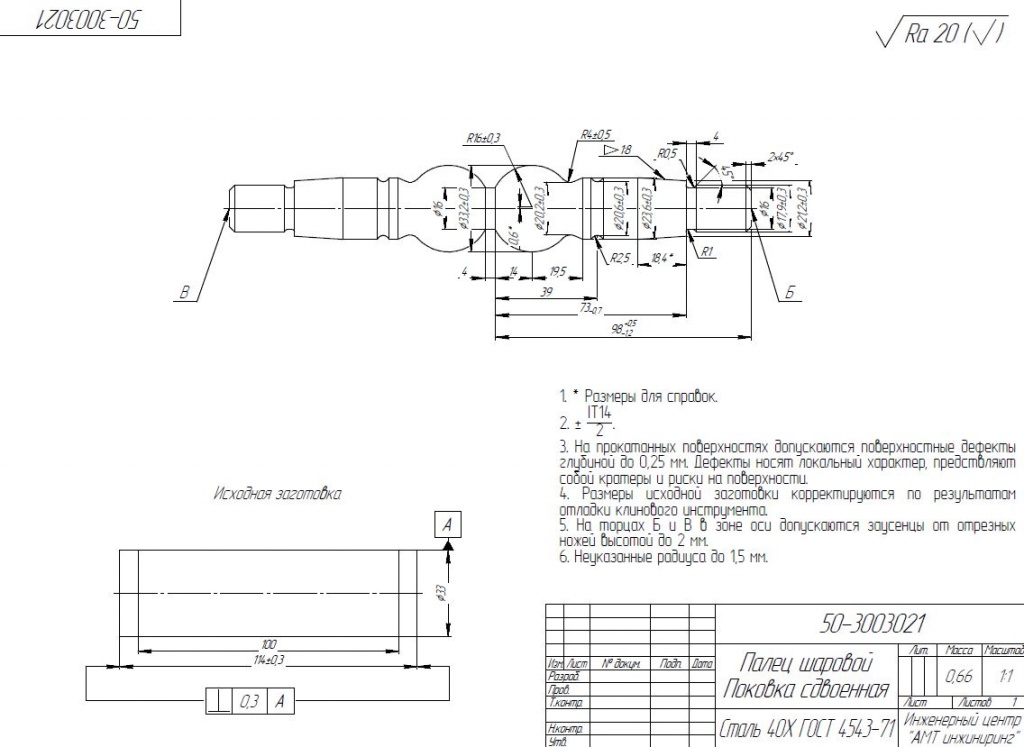

Examples of rolled forgings of ball pins of stabilizer struts. Rolling of two pins in pairs in one pass.

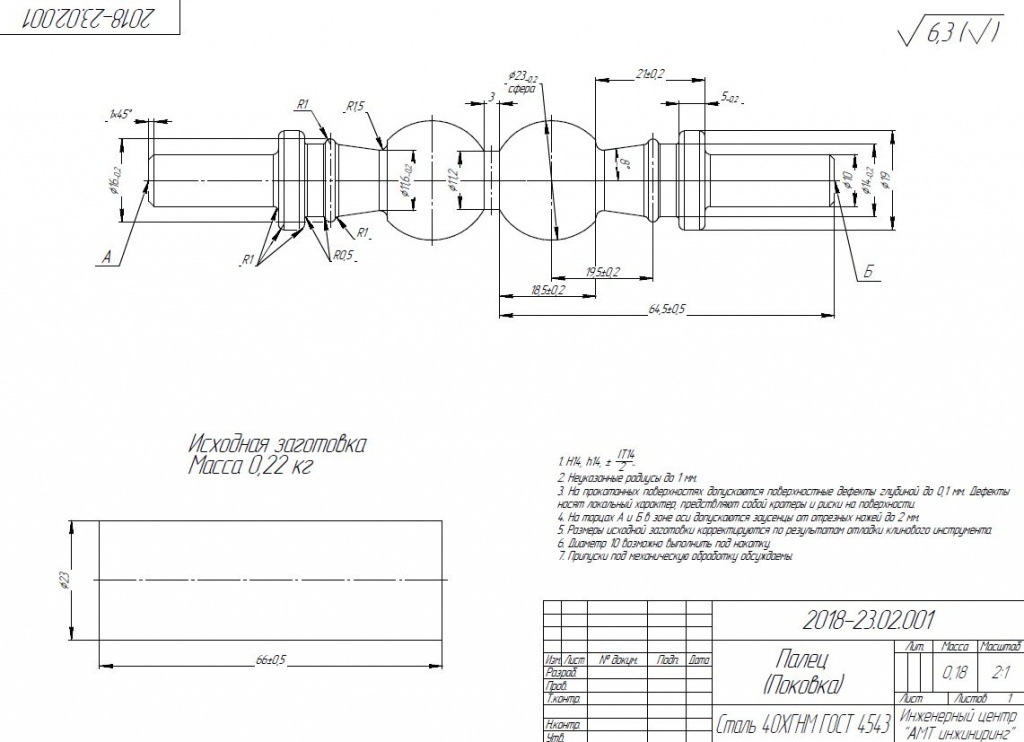

Ball pin option. Ball bolt.

Option 2. Cross-wedge rolling line WRL4012 or WRL4013 for rolling ball pin forgings with a maximum diameter of up to 40 mm. Feeding the workpiece into the inductor from a storage chute or storage bin.

Cross-wedge rolling line WRL4012 or WRL4013 consisting of:

- Rolling machine;

- Machine loading device;

- Induction heater with thyristor frequency converter (TFC);

- Inductor loading device with feed from the blank accumulator;

- Device for automatic feeding of blanks into the rolling machine with sorting by temperature. Device for monitoring the temperature of the blank with a pyrometer and a mechanism for removing underheated or overheated blanks coming from the output section of the inductor;

- Rolling tool changer.

Purpose indicators:

- Installed capacity of the rolling machine and TPC, kW 320

- Productivity for single rolling of forgings, pcs/hour 360…450, for paired 720...900

- Automatic cycle time, sec 8…10

- Blank heating temperature, 0С 1000…1200

To organize the annual production of ball joint pins of about 5 million pieces, it is necessary to purchase specialized equipment:

- WRL4013 cross-wedge rolling lines (new equipment manufactured by AMTengineering) consisting of automatic feeding of blanks, heating and rolling lines 2 pcs;

- 2-spindle lathes 16 pcs. (made in China UNIMATIC MT65).

- 19 single-spindle lathes (made in Taiwan).

- heat treatment line TG-10 (made in Germany) – or similar.

- two assembly lines to ensure the release of 5 million units per year

- thread rolling machine "D-15" – 2 units (made in Taiwan)

- band saws for cutting blanks (BOMAR, Czech Republic) or similar.

- To organize the assembly and ensure the release of about 5 million units per year of ball joints, 2 assembly lines are required.

To check the quality control of manufactured products, test stands are required:

- stand for the cyclic durability of ball joints;

- stand for the cyclic durability of rubber covers;

- stand for static and dynamometric loads.

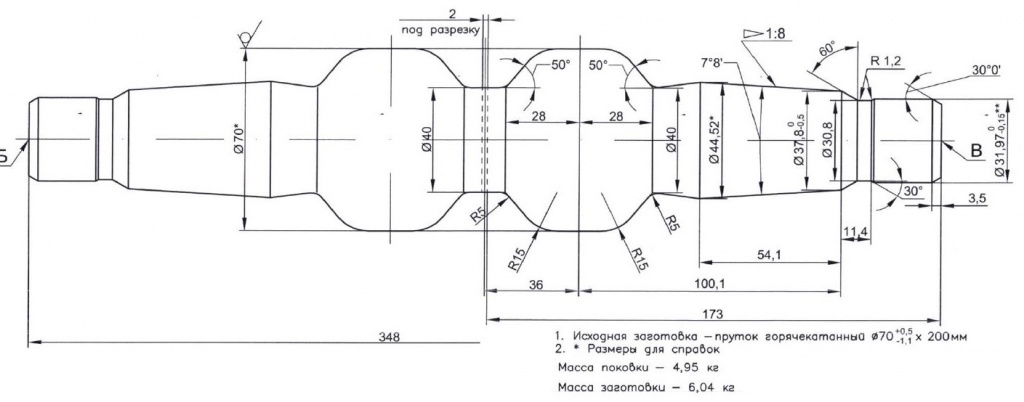

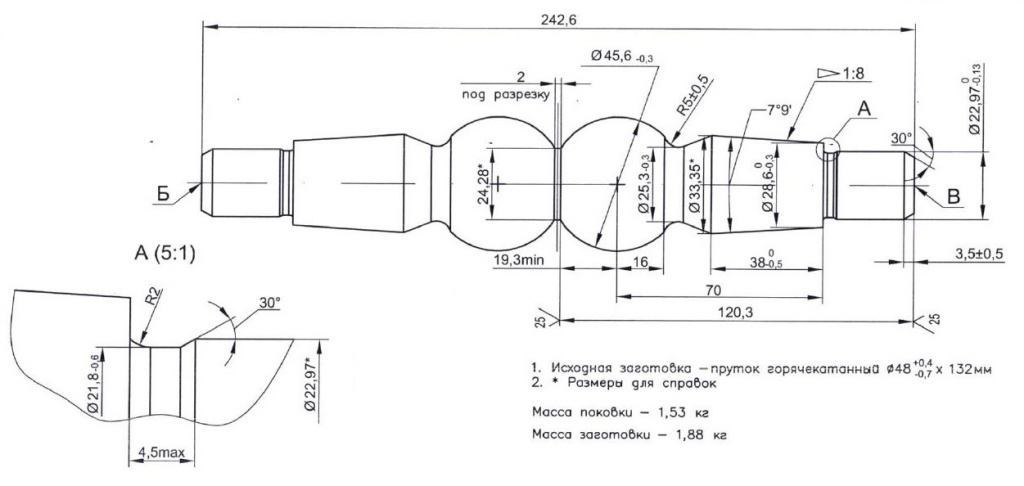

Examples of rolled ball pin forgings.

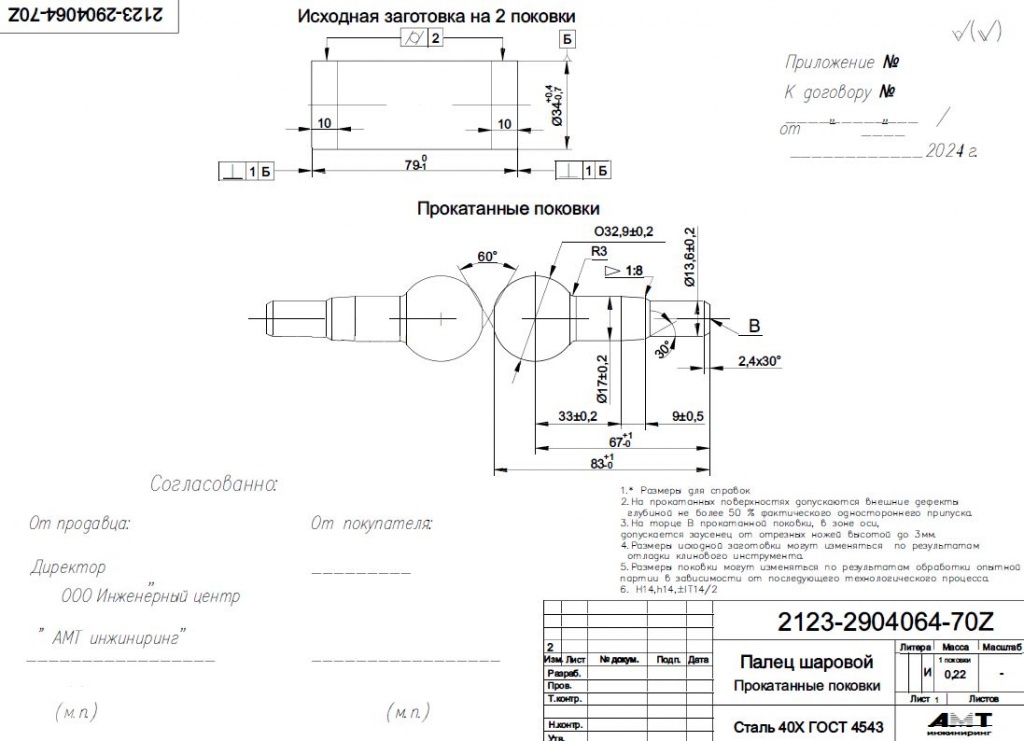

Examples of rolled forgings of ball pins 2123-2904064

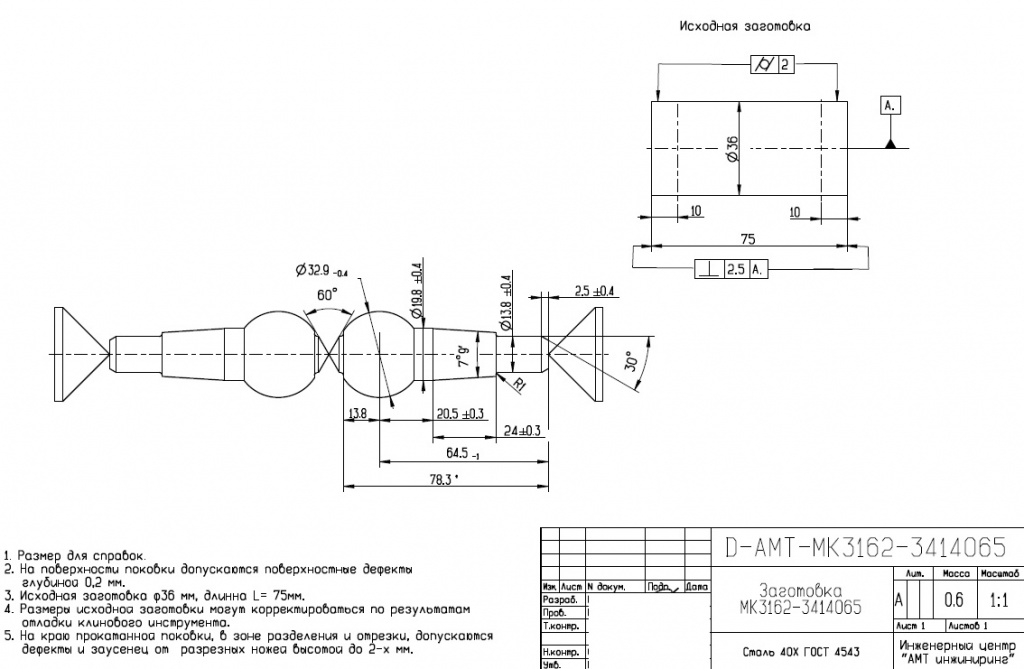

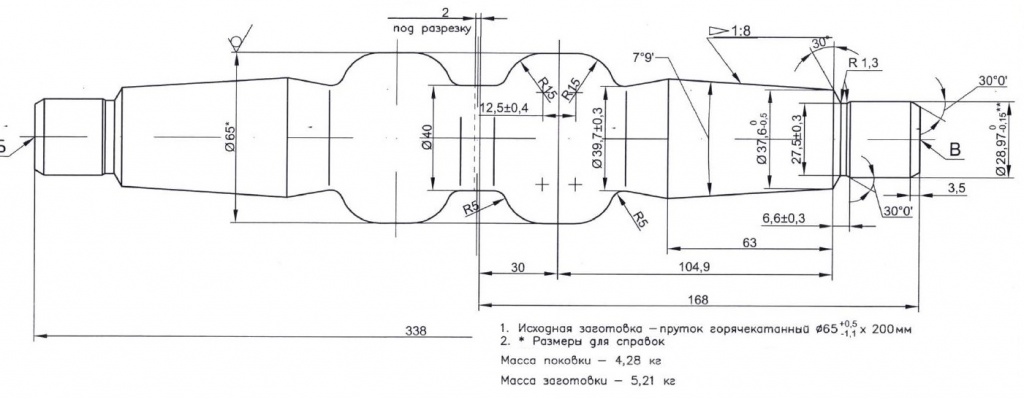

Examples of rolled forgings of ball pins MK3162-3414065

Option 3. WRL8012 cross-wedge rolling line for rolling ball pin and bearing forgings with a maximum diameter of up to 60 or 80 mm. Feeding the workpiece into the inductor from a storage chute or storage bin. Used for rolling forgings for trucks and buses.

Cross-wedge rolling line WRL8012 consisting of:

- Rolling machine;

- Machine loading device;

- Induction heater with thyristor frequency converter (TFC);

- A set of replaceable inductors for workpieces with diameters of 35 ... 55 mm and 55 ... 80 mm;

- Inductor loading device with feed from a workpiece accumulator;

- A device for automatic feed of workpieces into the rolling machine with sorting by temperature. A device for monitoring the temperature of the workpiece with a pyrometer and a mechanism for removing underheated or overheated workpieces coming from the output section of the inductor;

- Rolling tool changer.

Purpose indicators:

- Installed capacity of the rolling machine and TPC, kW 920

- Productivity for single rolling of forgings, pcs/hour 180…200, for paired 440...480

- Automatic cycle time, sec 15…30

- Blank heating temperature, 0С 1000…1200

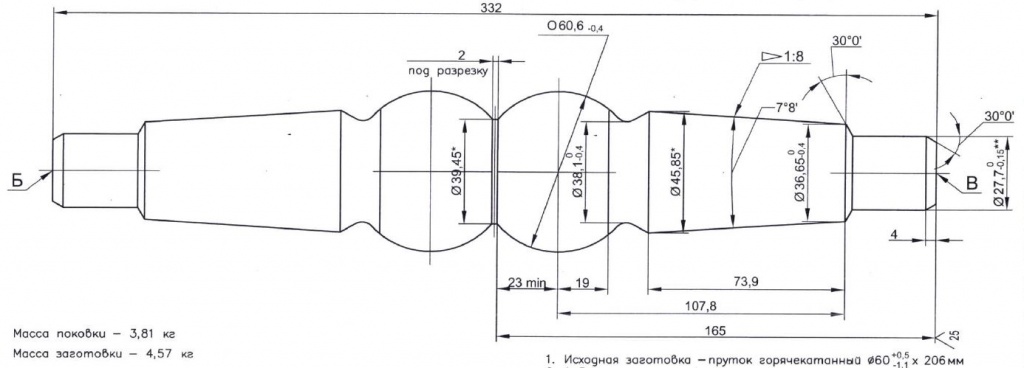

Jet thrust finger

Pin of jet thrust 2 of cargo equipment

Torque Rod Pin 5511-291903 Trucks

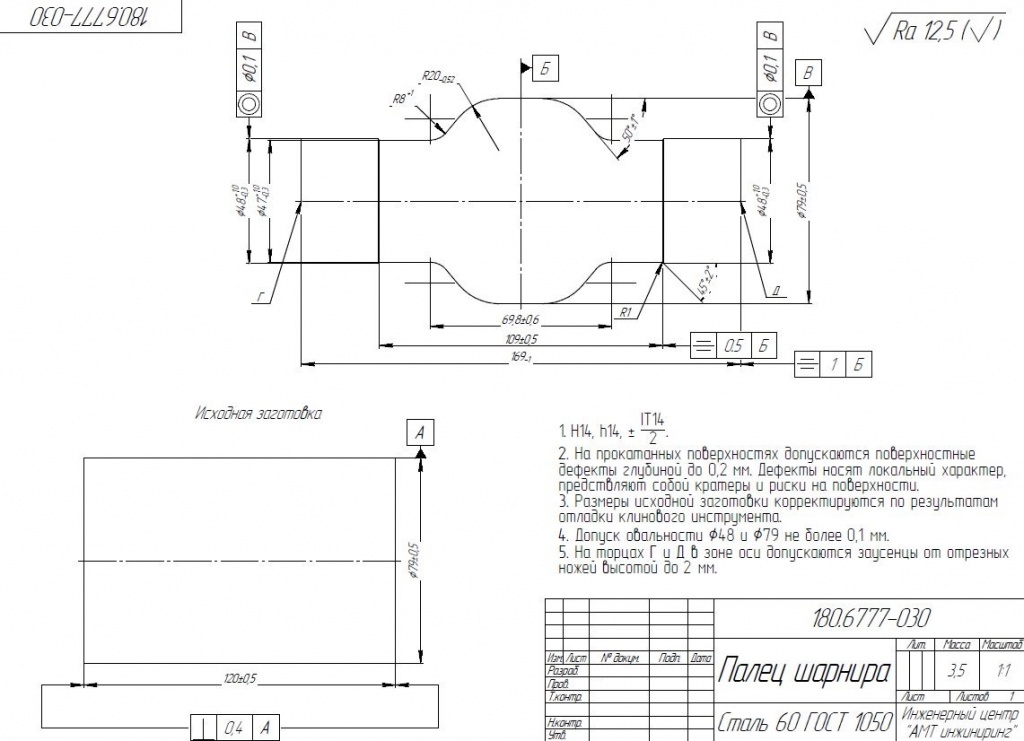

Hinge pin 180.6777-030 for trucks

Ball joint for trucks

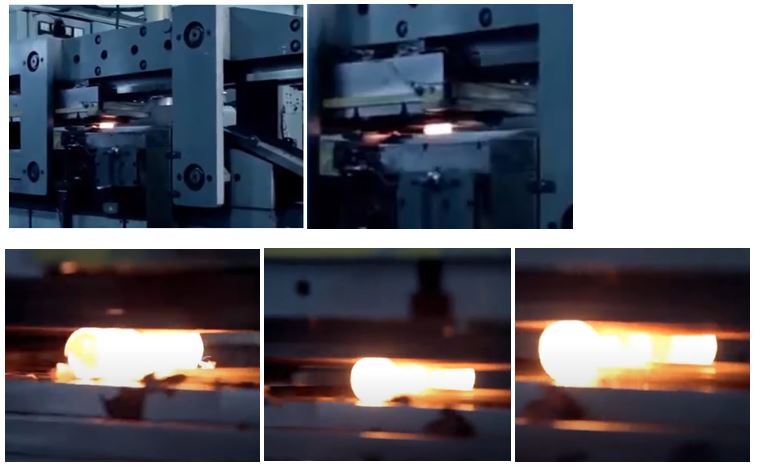

Example of dimensions of rolled forgings of ball joints and pins. Parts without mechanical processing. The surface quality shown in the photo is obtained in one working cycle of cross-wedge rolling.

An example of using cross-wedge rolling lines for serial production of ball pins and bearings

An example of the use of AMTengineering cross-wedge rolling lines at the customer's production sites for the production of ball pins, supports, thrust pins, etc.

Our rolling lines are universal, due to the quick change of tools, they allow us to reduce the time for changing the range of products being manufactured. We design and manufacture rolling lines and tools ourselves, and launch the line at the customer's site, which significantly simplifies the coordination and implementation of projects. Our production lines, delivered to the customer back in the 90s and 20s, are operated at our customers' sites.

If you are interested in implementing cross-wedge rolling lines, please let us know in any way convenient for you.

We are interested in supplying equipment for the production of auto components to Vietnam, the Philippines, India, Türkiye and other countries of the near and far abroad.

CONTACTS:

- Phone: +375 (25) 500-15-23 (Viber and WhatsApp)

- E-mail: amtengine@amtengine.com